MAJiK Visual Factory

MAJiK Systems

MAJiK Visual Factory

MAJiK Systems

MAJiK Visual Factory

MAJiK Systems

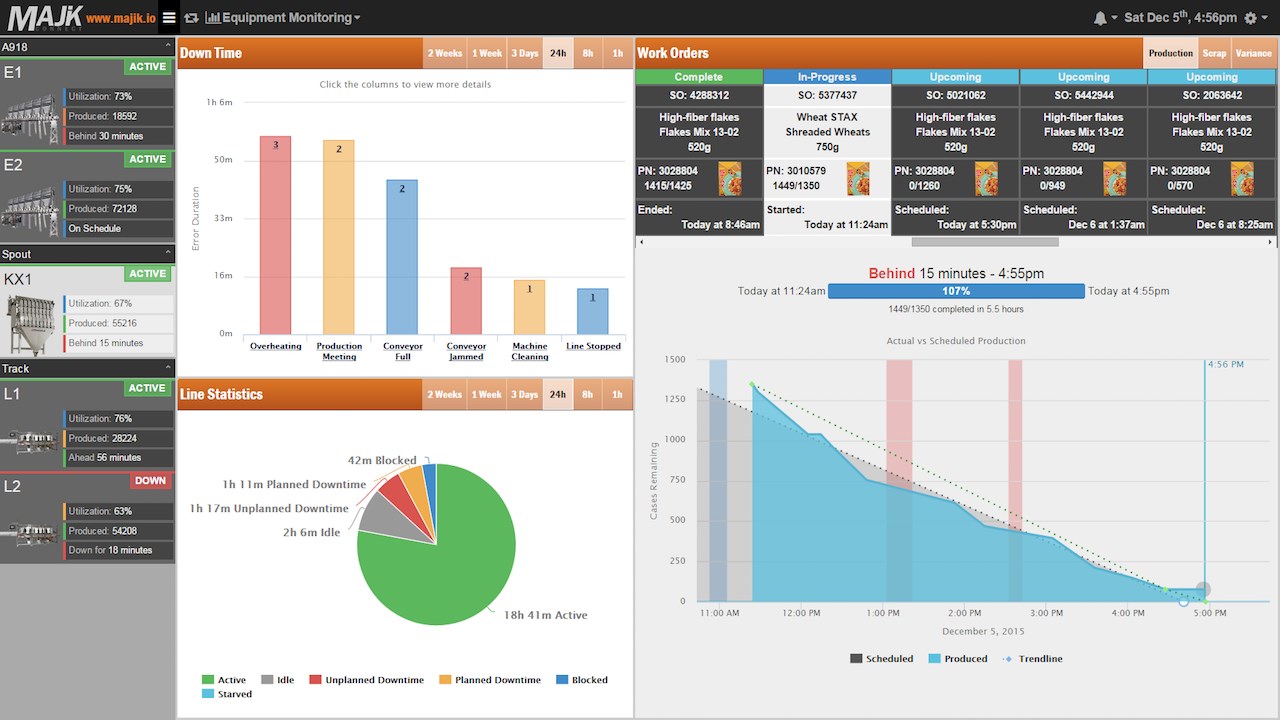

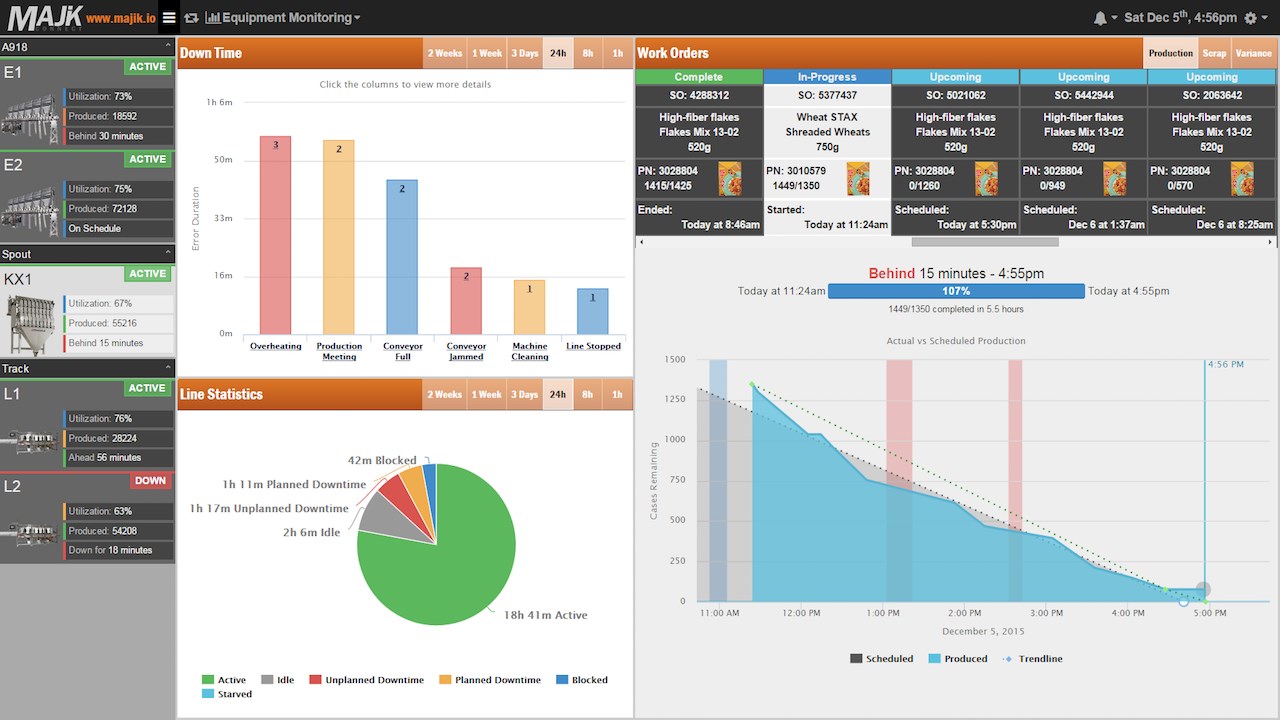

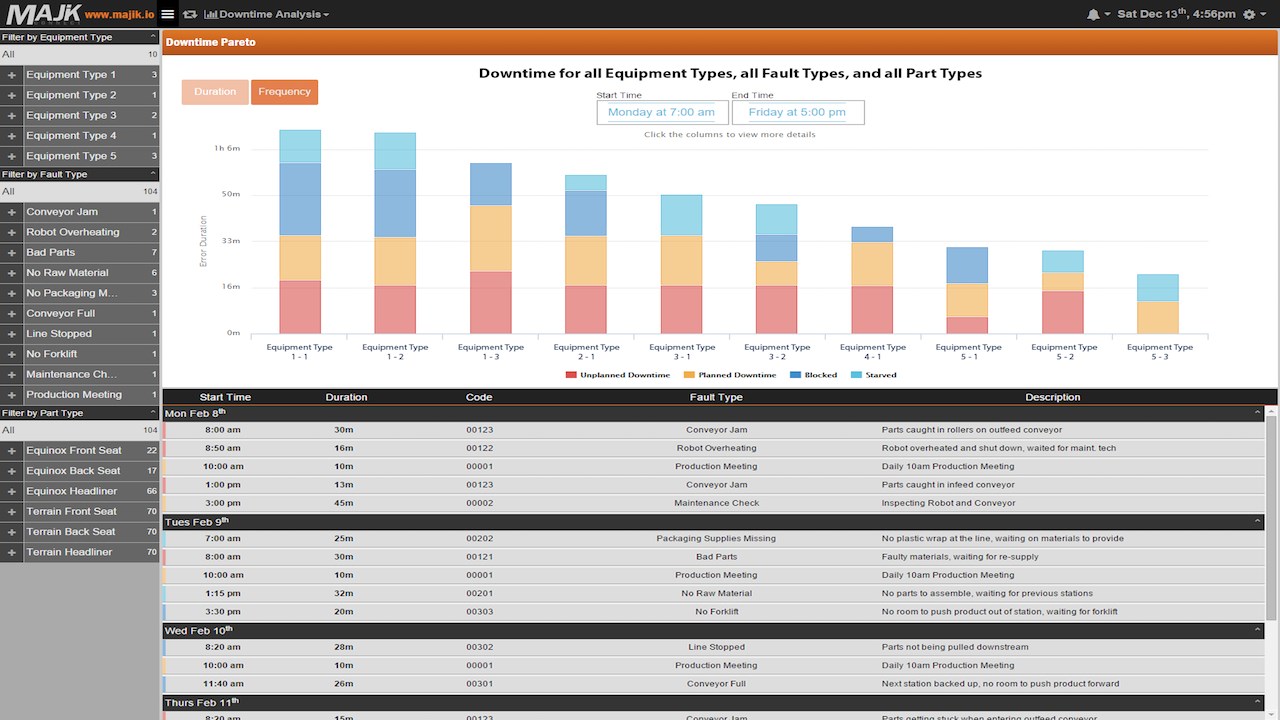

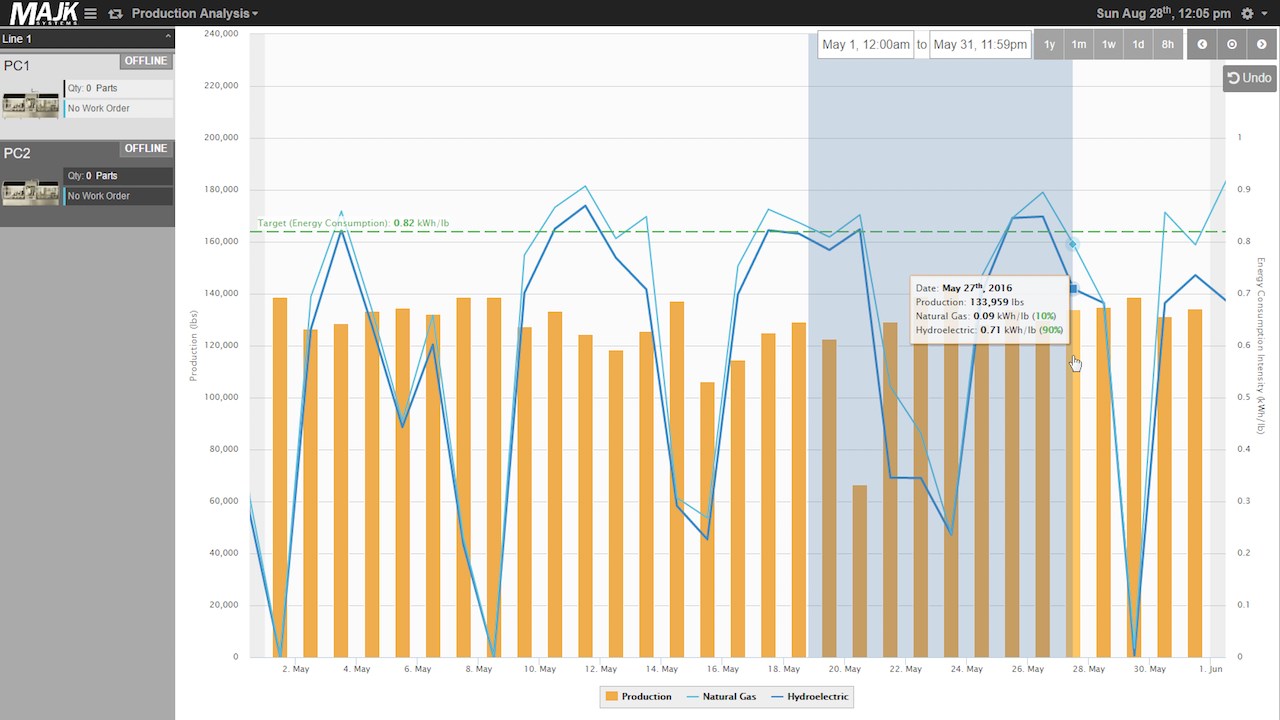

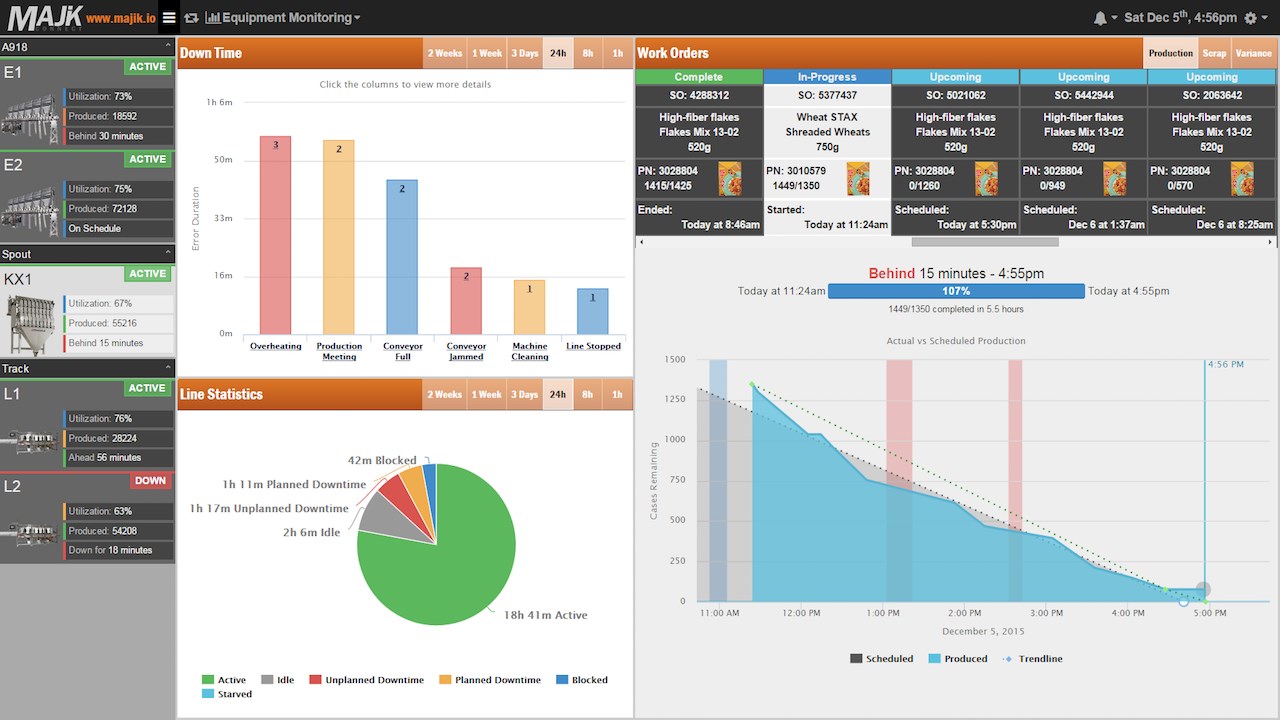

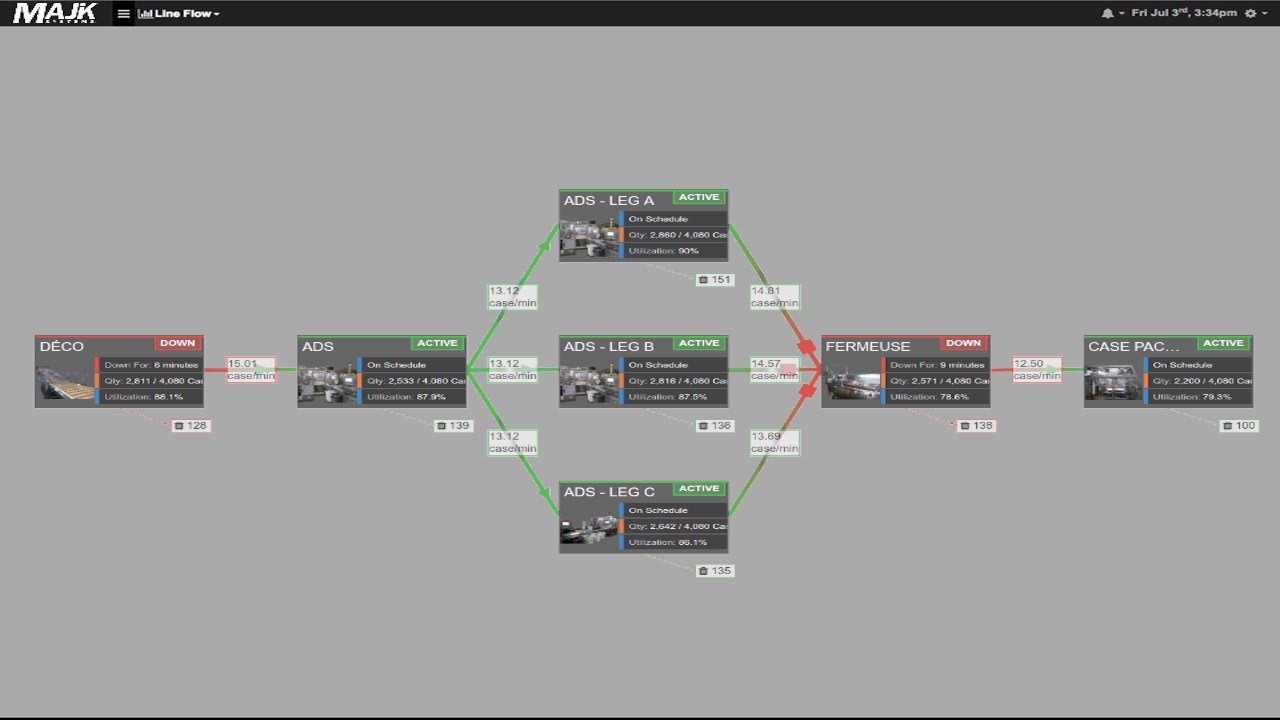

Monitor, Analyze, and Optimize Your Factory Using Real-Time Dashboarding and Analytics

MAJiK Systems' Visual Factory Software connects directly to capital equipment in your plant to retrieve and normalize manufacturing data from any PLC, HMI, CNC, SCADA System, or Factory Information Database.

This data is provided to you within Microsoft Azure using out-of-the-box configurable web-based Dashboards and Analytics to help you Monitor, Analyze, and Optimize your manufacturing processes in real time.

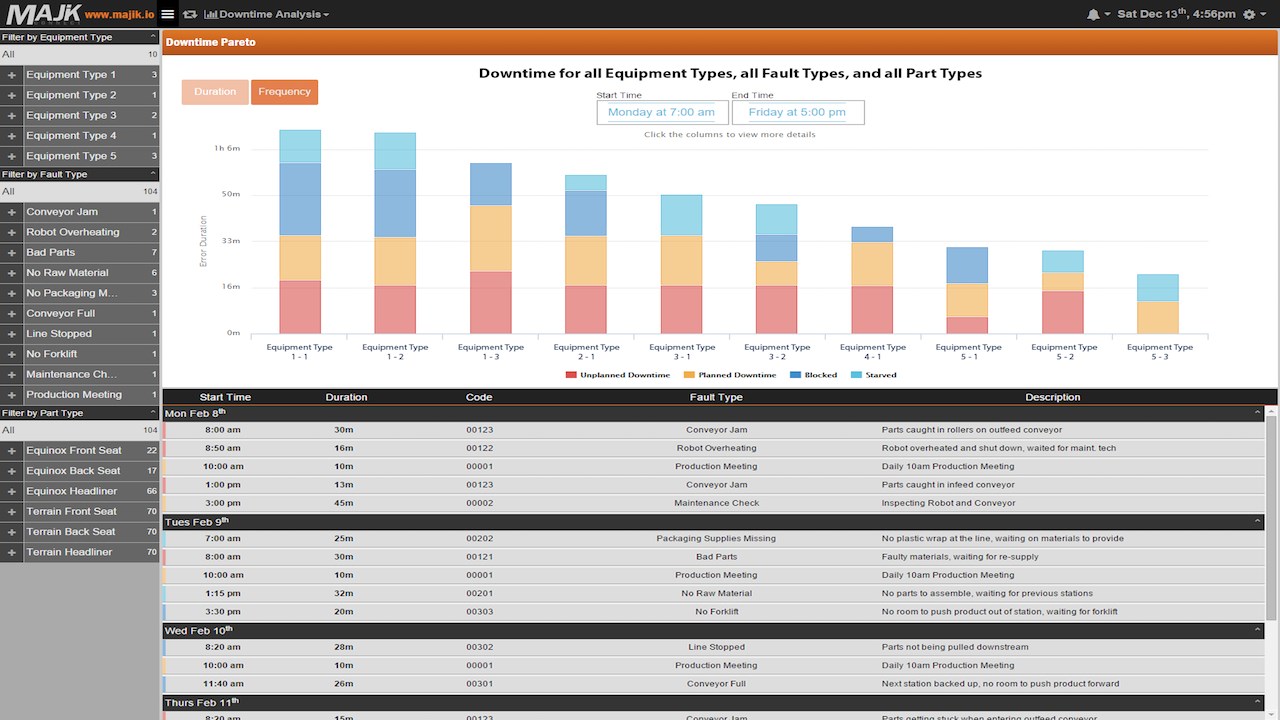

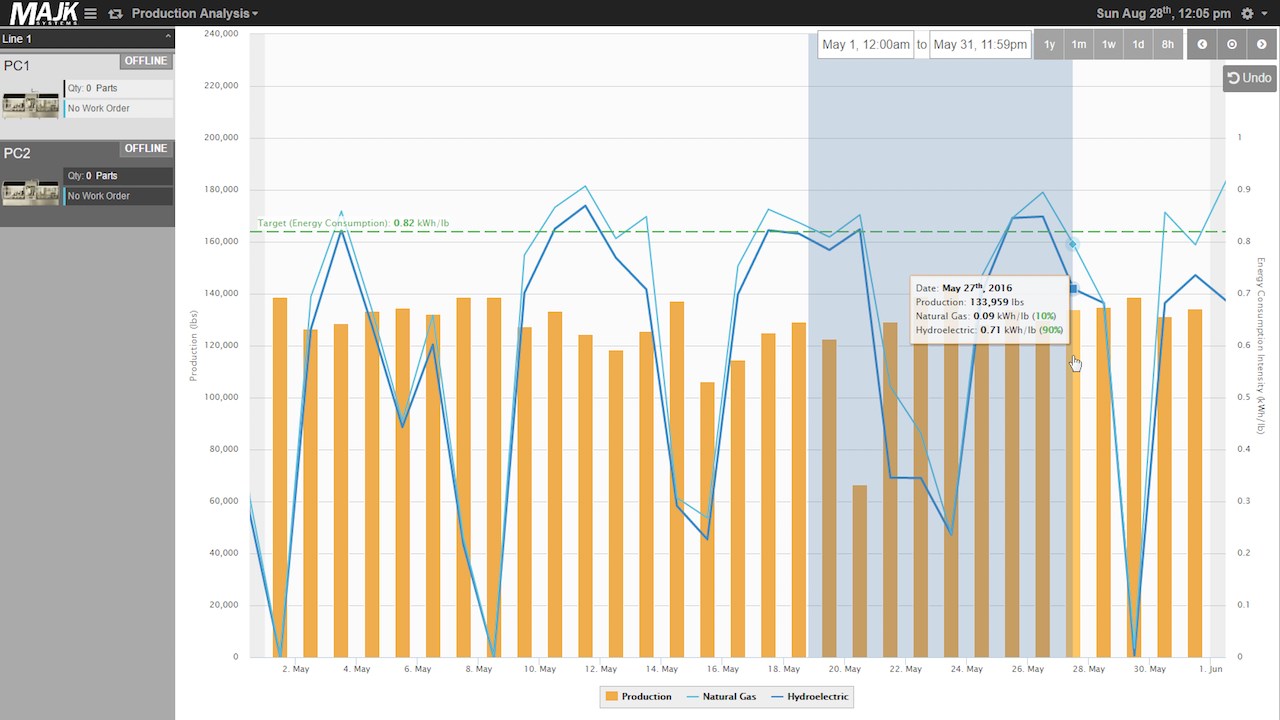

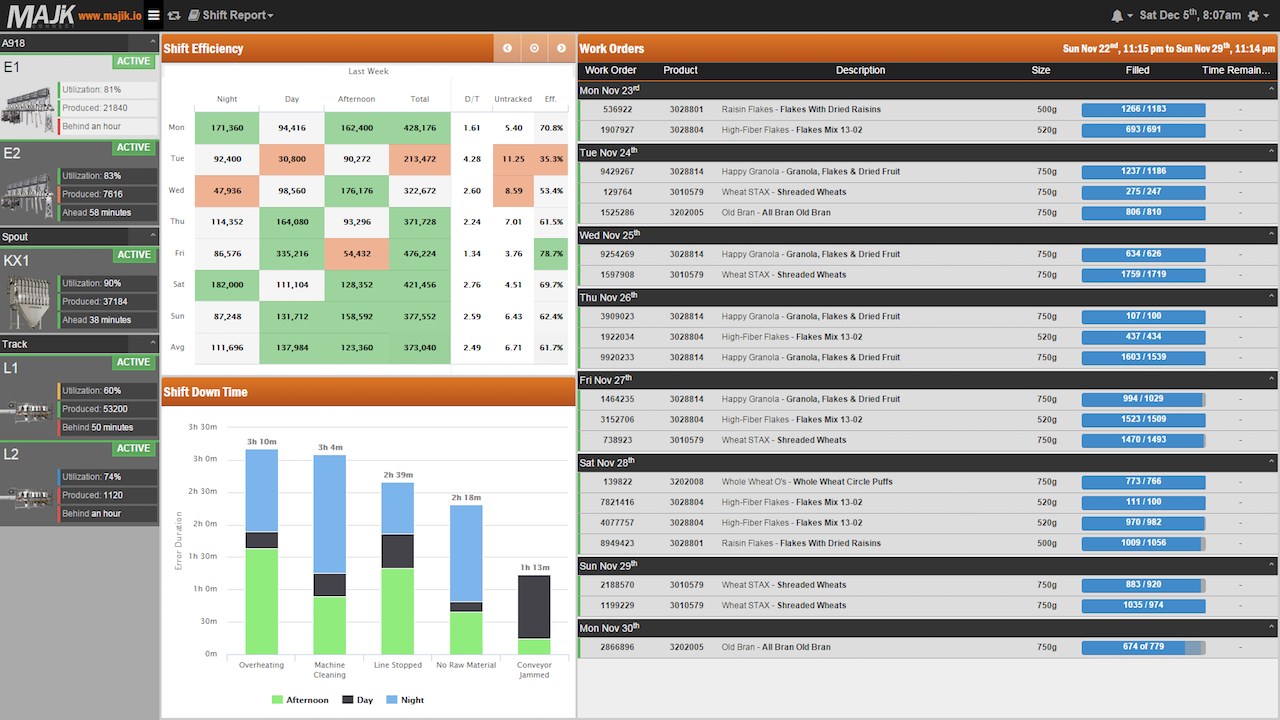

Track Production, Schedule Performance, Downtime, Scrap, and other Key Performance Indicators, as well as collect low-level machine telemetry data such as Temperatures, Pressures, Tool Position, Vibration, and more to enable AI-Based continuous improvement techniques such as Predictive Maintenance or Dynamic Scheduling.

Receive mobile notifications and automated reports on your smart-phone, or dive in to detailed reports and dashboards in your web browser from anywhere in the world. Motivate your employees with easy-to-understand line-side displays and tablet-friendly apps.

Use Azure Solution Accelerators to build your own reports, analytics, and applications on top of MAJiK's Visual Factory to increase the adoption of Data-Driven Manufacturing across your organization.